Steam Trap Surveys: Improve Efficiencies and Reduce Costs

Download FlyerSchedule your Steam Trap Survey Today 712-252-4797

Annual inspections are recommended.

Key Benefits:

- Energy and Cost Savings: reduce energy waste, lowering operational costs.

- Reduced risk of system failures.

- Enhanced System Performance - ensure consistent and reliable operation.

- Reduced emissions - returning condensate conserves energy, and reduces water and chemical usage.

- Safety Compliance - meet industry standards and regulations.

- Maximum Uptime: quick, reliable component replacement.

- Improved Productivity and Process Efficiency: healthy traps optimize thermal energy delivery.

When was the last time your steam traps were checked?

Steam traps are tested primarily to determine whether they are functioning properly and not allowing steam to blow through. By identifying and fixing faulty steam traps, you can prevent energy waste and ensure your boiler system operates at peak efficiency.

A detailed steam trap survey can uncover hidden efficiencies and help you save energy and costs!

Call 712-252-4797 to schedule your steam trap survey today!

Prevent Loss, Save More:

Systems neglected for 3-5 years can have 15% to 30% of steam traps fail, leading to substantial steam loss. Regular Steam trap surveys and maintenance can reduce this to less than 5%.

Systems with over 500 traps are likely experiencing significant steam losses.

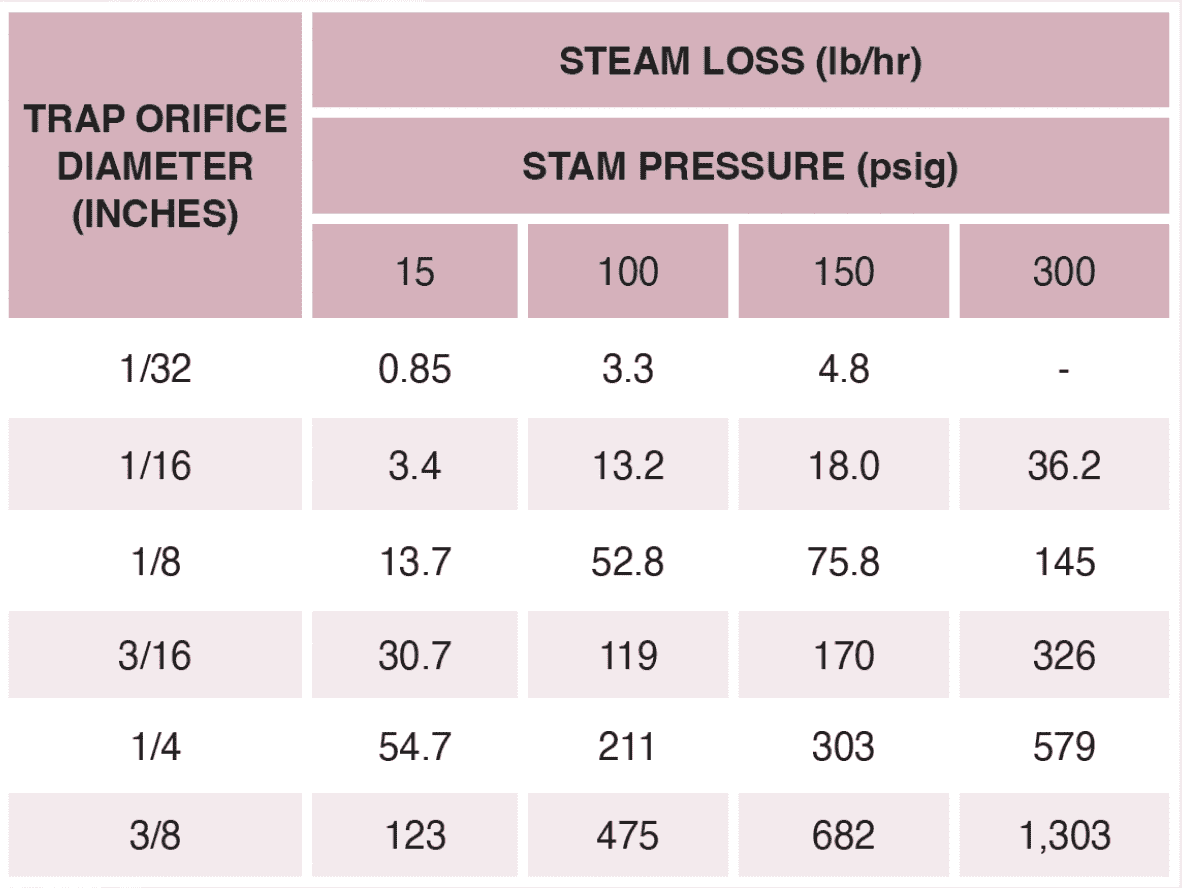

A case study at a plant, where steam is valued at $10 per 1,000 lbs, highlighted a stuck steam trap on a 150 psig line. Repairing it resulted in annual savings of $6,640.

Source: US Department of Energy_2012 Case Study

Leaking Steam Trap Discharge Rate *

From the Boiler Efficiency Institute. Steam is discharging to atmospheric pressure through a re-entrant orifice with a confficient of discharge equal to 0.72.

Excellence In Boiler Service

Our skilled service technicians excel in servicing all makes, models and types of boilers, specializing in the entire system, including the steam trap. Trust our expert technicians to maintain efficiency and safety in your boiler system.

With our comprehensive inspection, testing, and repair program, we can help you maintain system efficiency, safety, and compliance.

How does a steam trap work?

By opening a valve, the steam trap allows condensate to pass through, collecting it and returning it to the Condensate Tank, Deaerator (DA) or Feed Tank while filtering out any non-condensable gases. This prevents steam loss, water hammer, and corrosion, while improving overall efficiency. In commercial, industrial, and institutional settings, there can be upwards of hundreds of steam traps, which can result in substantial annual savings.